Cell Monitoring Unit

CMU - QUT Motorsport

Joint project with Thomas Hulbert

Introduction

The CMU performs several critical functions:

- Communicates with slave cell monitoring units via IsoSPI

- Filters and monitors cell voltages and temperatures

- Executes cell balancing algorithms

- Interfaces with the charger for state management and precharge commands

- Manages shutdown interfaces for IMD, PDOC, connector interlocks, and BMU battery state with detection capabilities

Design Requirements

FSAE Rules 2023

At QUT Motorsport, the 'Accumulator Management System' combines the BMU and CMU.

The AMS system must have galvanic isolation at every segment to segment boundary.

IPC Design Clearance Specifications

- 0.6mm spacing for nets ≥31V

- 0.1mm for nets ≤30V

Team Design Requirements

Revision B - QEV-3 Only

Previous generation used a BMU chip, microcontroller, and CANbus architecture. Revision B addressed systemic issues, monitoring 10 of 14 cells and integrating with the QEV-3 battery assembly position.

Revision C

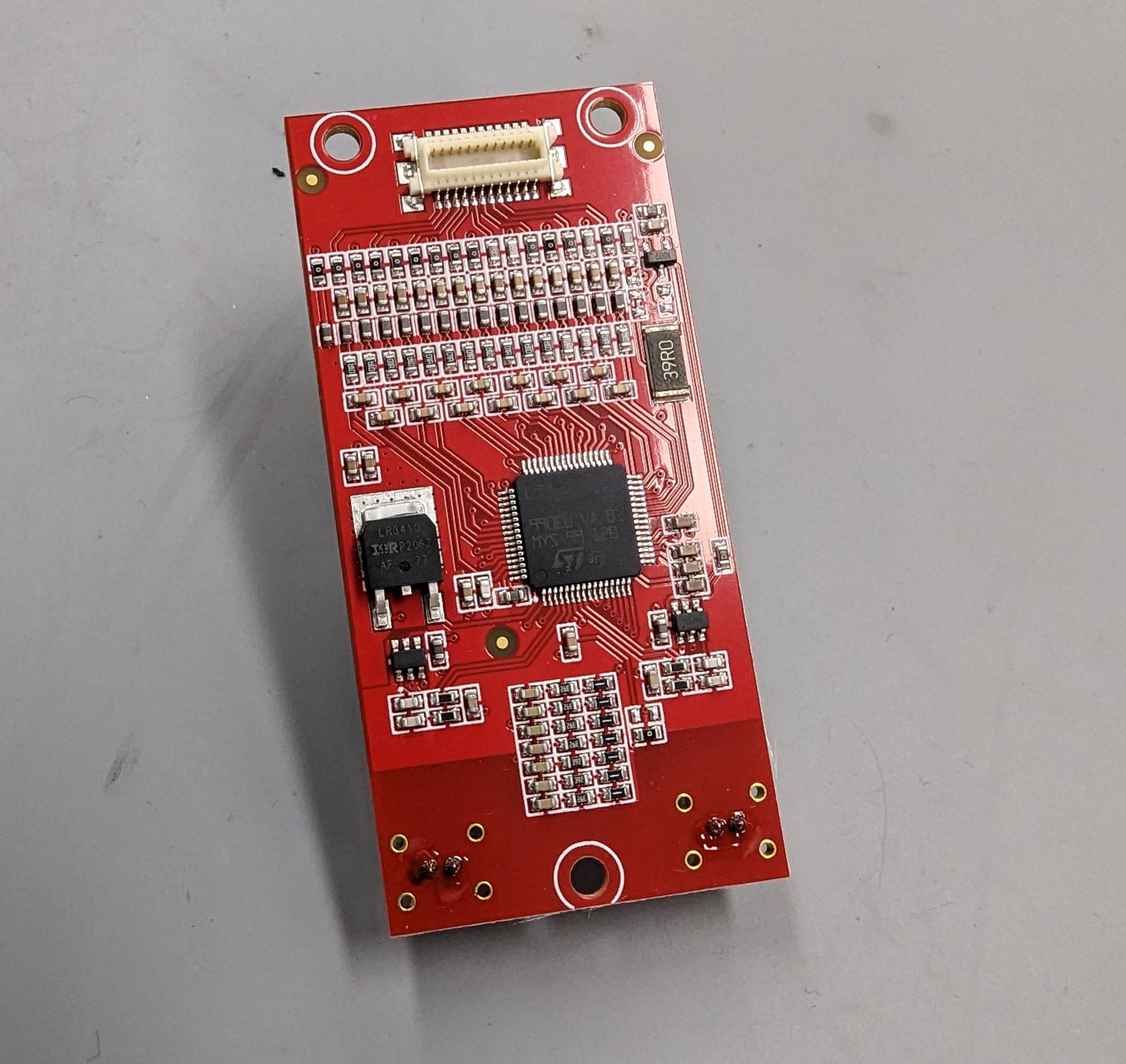

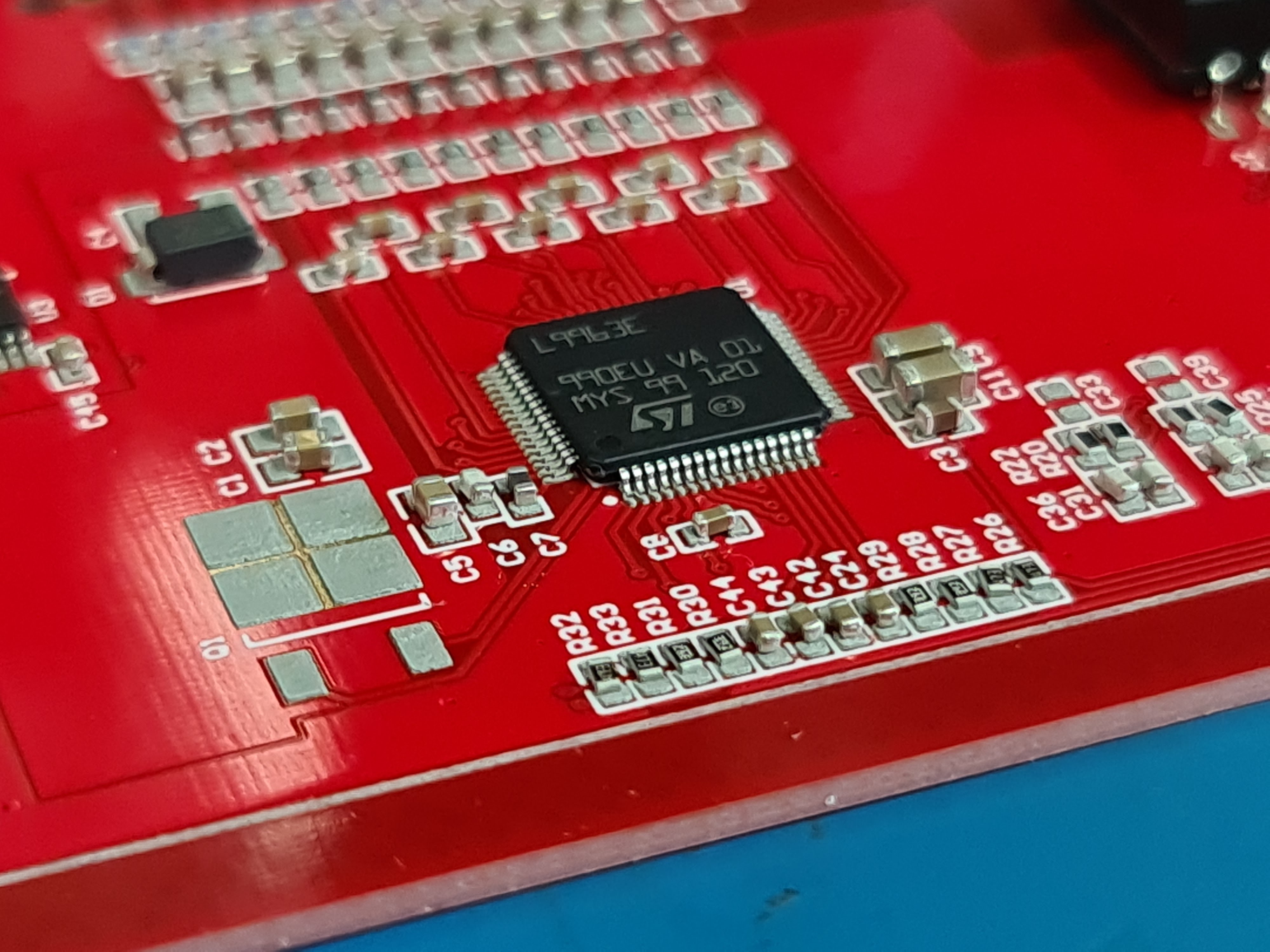

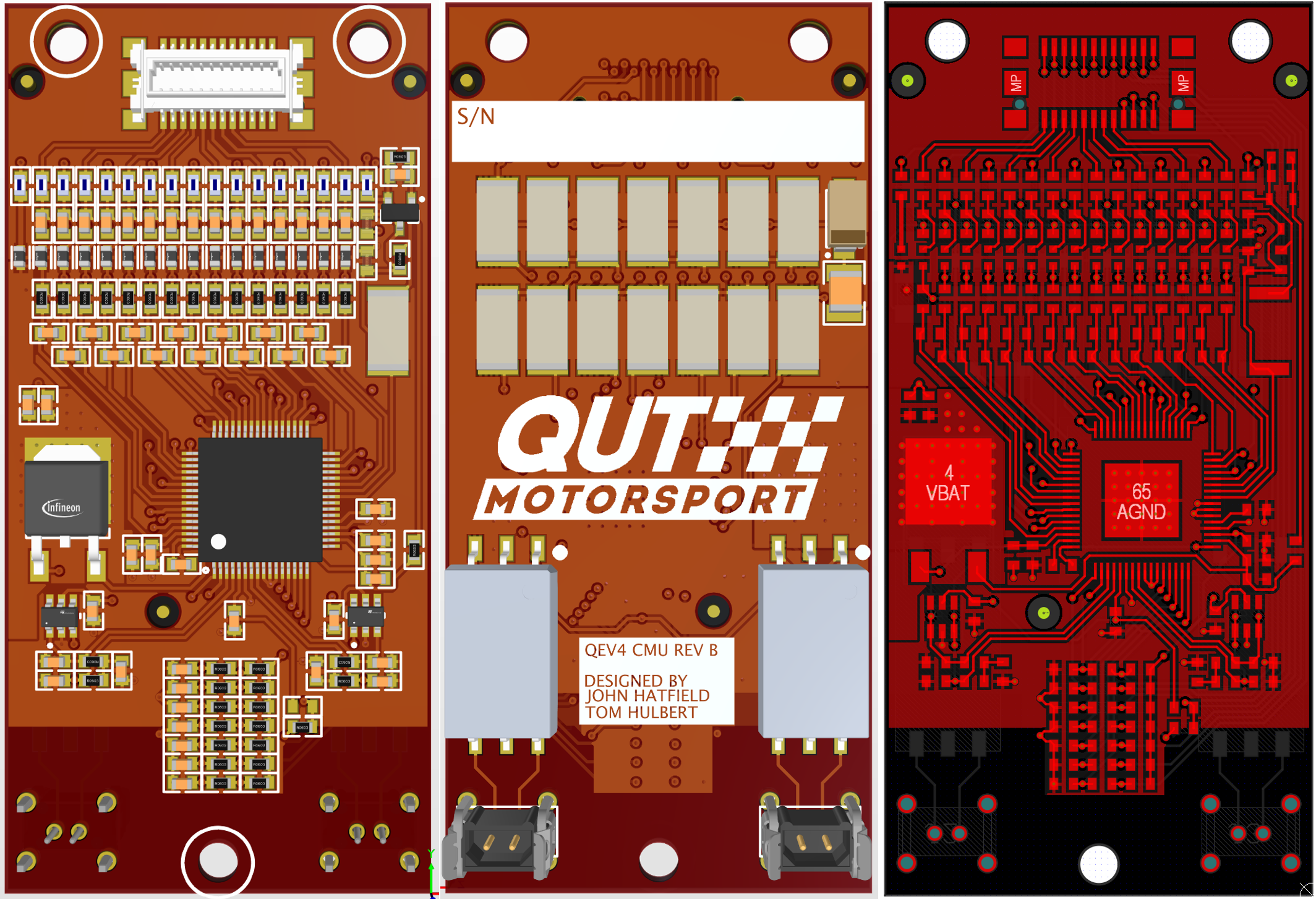

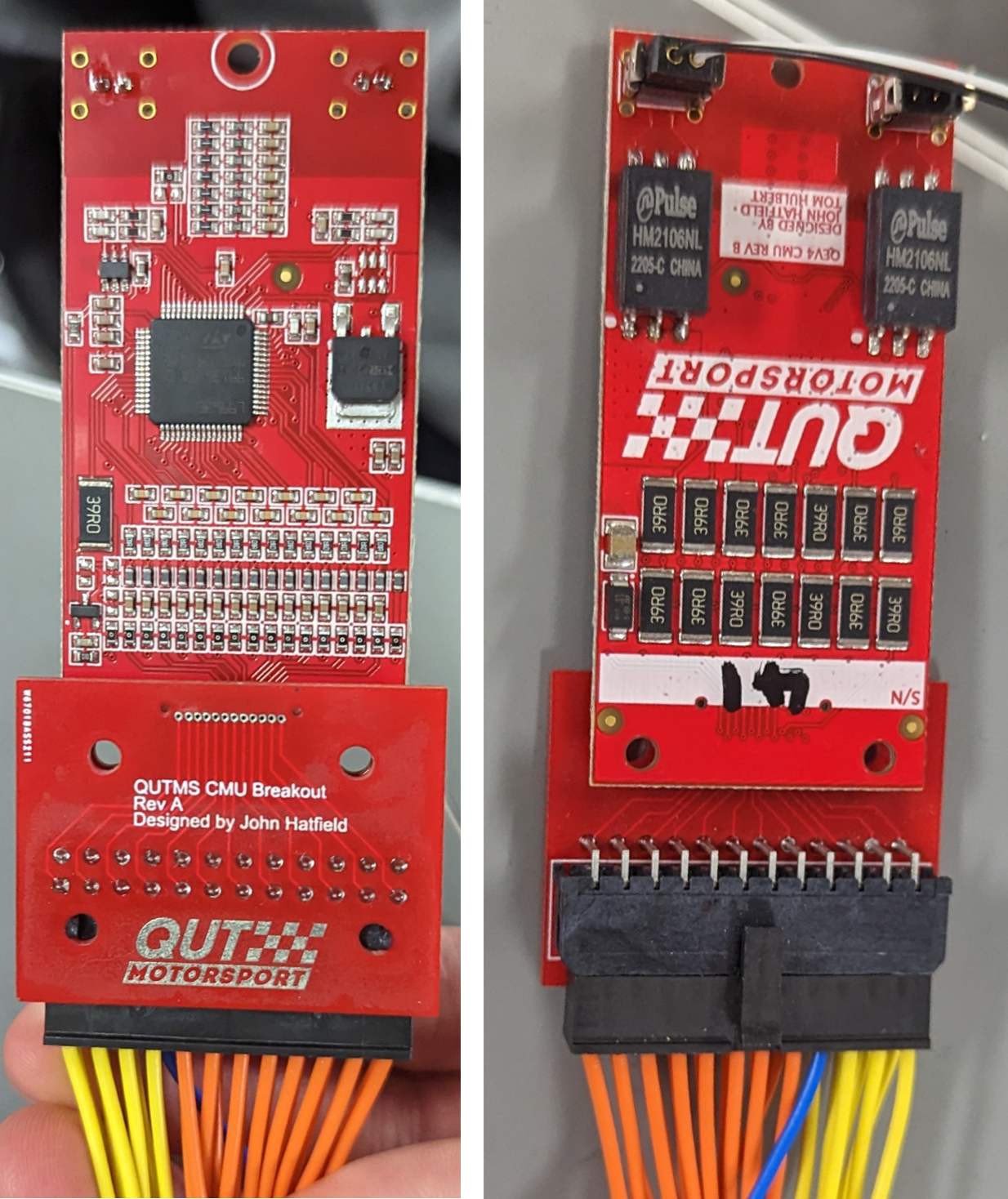

Designed for the QEV-4 vehicle with all 14 cells required. The L9963E implementation features a compact, double-sided design fitting atop the battery assembly with board-to-board connector or custom flex cable compatibility.

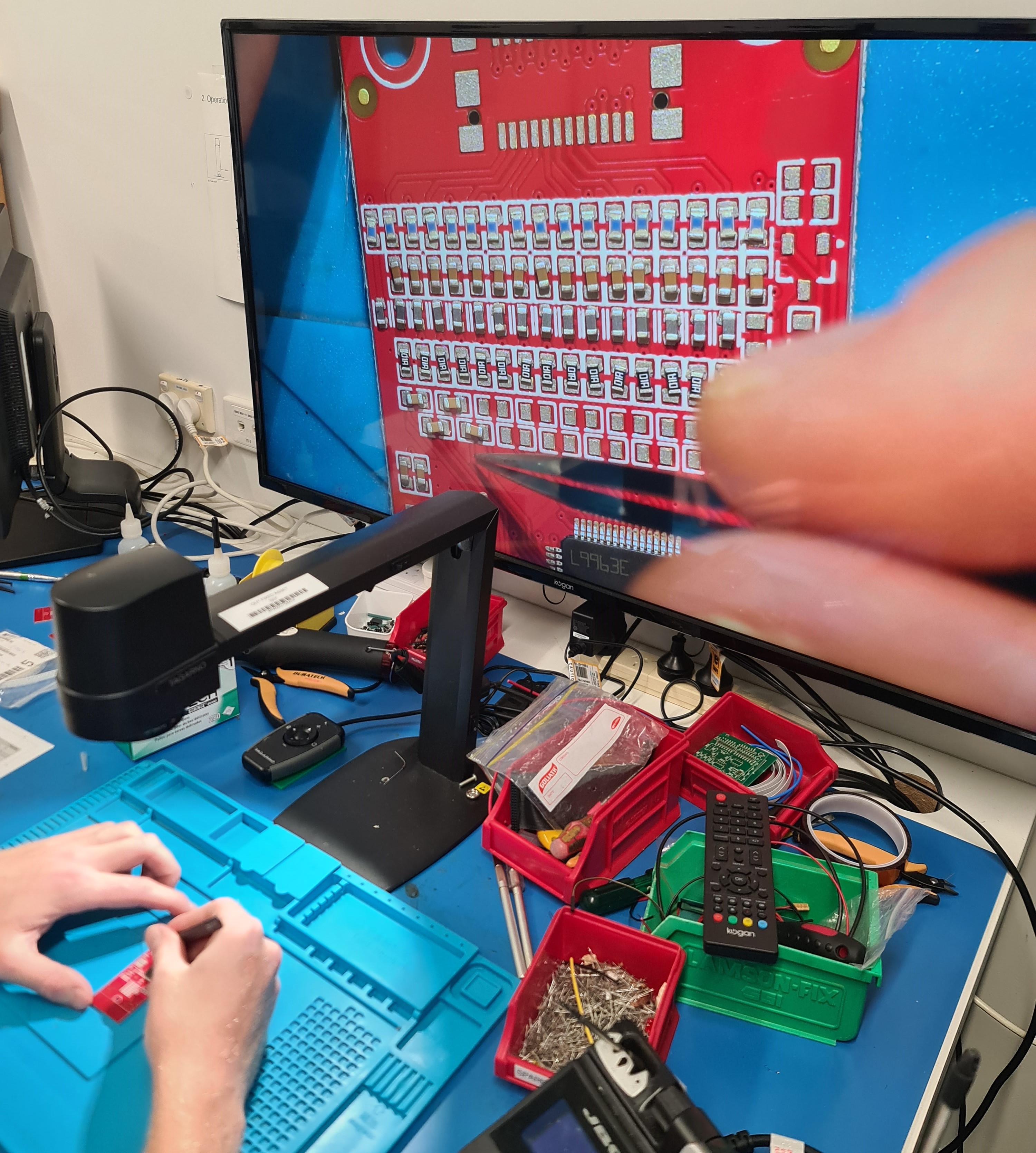

Prototype Assembly & Testing

Hand-assembled prototypes were reflowed in a vapor phase oven and validated using breakout boards for cell voltage and temperature readings.

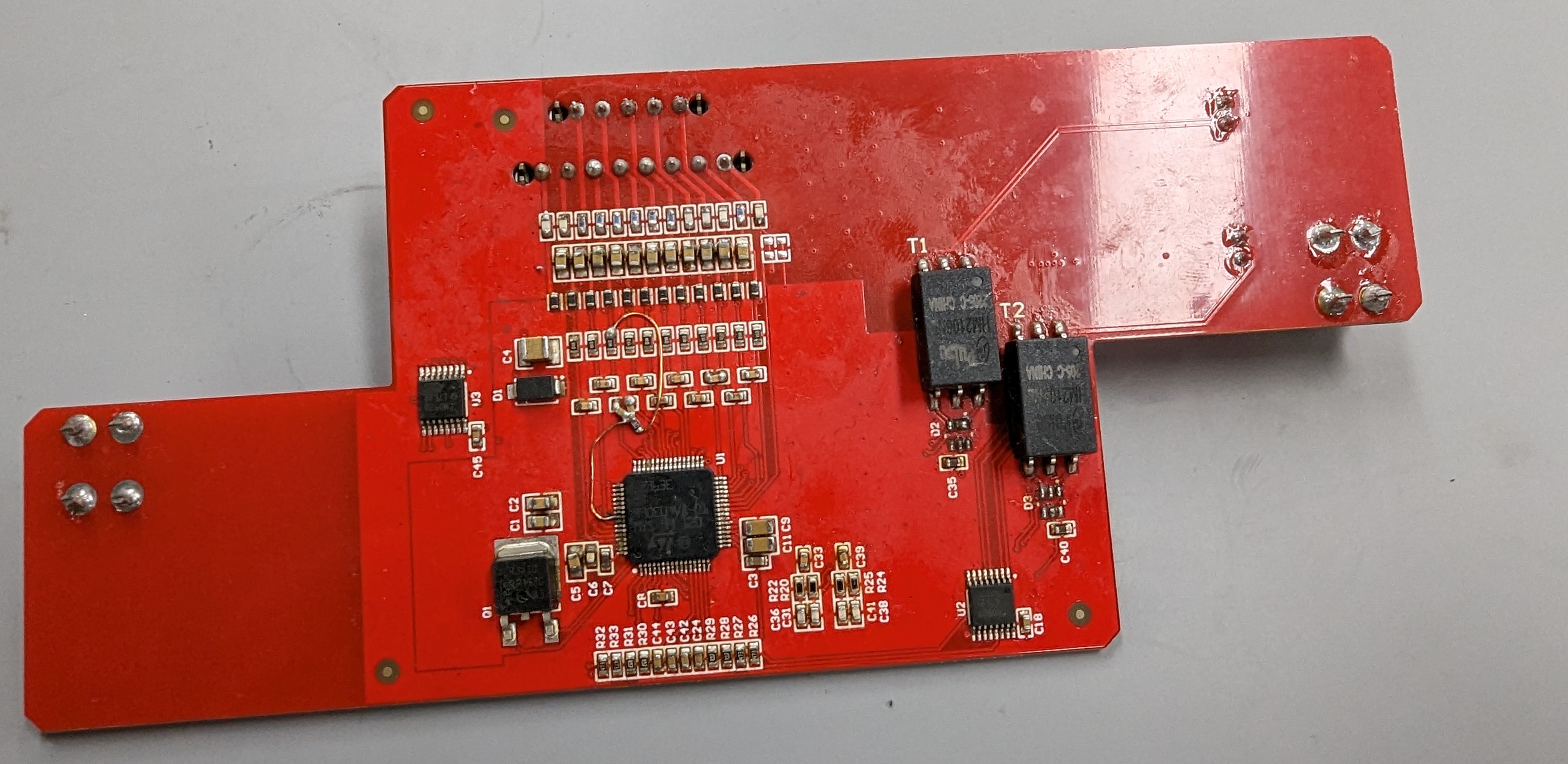

QEV-3 Adaptor

A carrier board connects 10 cells, ties remaining cells, and includes temperature multiplexing for the larger battery assembly.

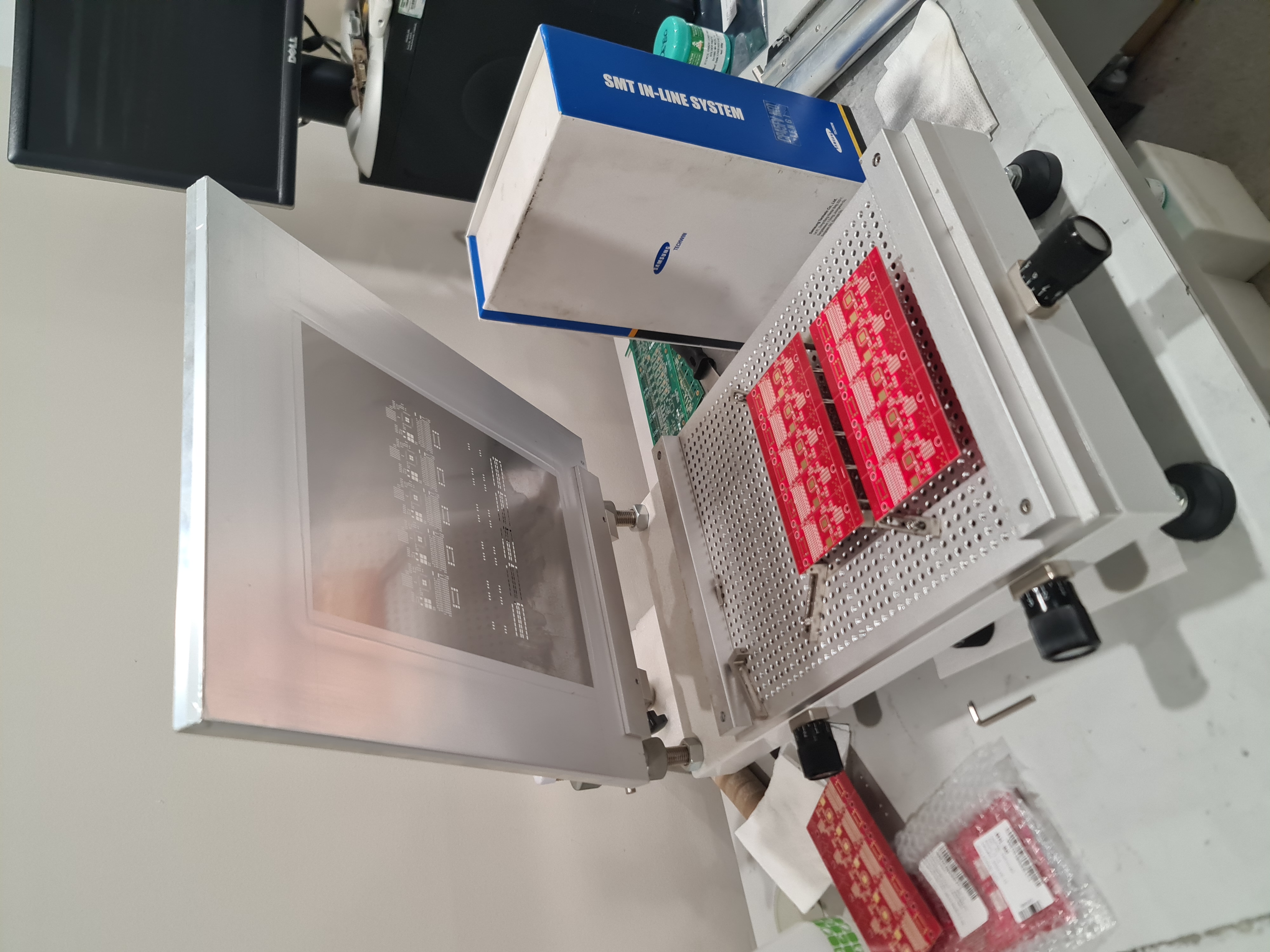

Pick and Place Assembly

Collaboration with Taylormade Electronics produced CMUs for QEV-3, QEV-4, and spares.

Schematics

Not published. Contact for details.